Resource efficiency and circularity

Mölnlycke is committed to the transformation towards a circular economy by designing products intended to stay in circulation through processes such as recycling. Our approach aims to decouple economic growth from the consumption of finite resources, by prioritising sustainable innovation that benefits both our partners and the planet.

Keeping materials in use

Partnerships with healthcare providers to reduce medical device consumption are key to Mölnlycke’s transition towards circular economy business models. Through appropriate selection and optimised use of our products utilising their entire service life, we aim to minimise waste and improve resource efficiency.

Designing for circularity

Through design for circularity, we pioneer solutions with renewable materials certified with International Sustainability and Carbon Certification system (ISCC) and the Forestry Stewardship Council (FSC) certification. Our portfolio of renewable and recycled material solutions will continually expand.

Exploring closed loop systems for medical devices

By collaborating with stakeholders, Mölnlycke is playing a key role in the development of closed-loop systems that aim to retain the value of resources in the healthcare system while reducing waste. These systems are designed to enhance resource efficiency, helping to ensure that more patients can benefit from finite resources without compromising product quality or safety.

Circularity targets

-

0recyclable packaging by 2030

-

0of packaging to be made of recycled or renewable material

Circularity outcomes 2024

-

0recyclable packaging

-

0packaging made of recycled or renewable materials

-

Our position statement on resource efficiency and circularity

Mölnlycke's ambition to decouple material use from its growth goes beyond recycling. It all starts with limiting the need to recycle. Therefore, we focus on zero waste, working in accordance with the ‘right first time’ principle and repurposing and reclaiming materials.

We’re on a journey to become a zero waste company, which involves focusing on both waste and water. We have an ambitious target of zero waste to landfill by 2030 as well as reusing water at all our most water-intensive sites by 2030 and we implement closed water loop systems in our production environments to that end.

Our waste reduction management programme to achieve the targets is based on site-specific activities designed to avoid waste being created in the first place and then minimising waste to landfill by correct segregation and disposing of remaining waste. We also identify new outlets for materials that would otherwise have been disposed of. Our actions make an important contribution to the UN Sustainable Development Goal on Sustainable Consumption and Production (SDG 12). To find out more, please see our integrated Annual and Sustainability Report 2024.

Our medical solutions often contain plastic or are delivered in diverse plastic packaging, with unique intrinsic performance properties which extend the lifespan of our solutions and protect them from external factors such as damage during transport and handling, or deterioration caused by contamination. This reduces the need for additional raw materials and resources in our products and contributes to minimising our customers’ waste.

As part of our resource efficiency journey, we have an ambition to provide >95% recyclable packaging by 2030. Governments around the world are adopting legislation targeted at tackling, for example, plastic waste. By embracing the power of upstream innovation to achieve two key circular economy innovation strategies — elimination and material circulation — we stay ahead of the curve. We continuously work together with customers, suppliers, recyclers, universities, and other partners to develop innovative and circular packaging solutions that have lower holistic environmental footprints and enable our customers to be more sustainable and deliver on their sustainability ambitions. These include a growing share of lighter, recyclable, recycled, bio-based and biodegradable solutions while guaranteeing best clinical outcomes.

We consider competition with the food chain when evaluating the use of bio-based renewable raw materials and preferentially select ISCC certified biobased materials, guaranteeing a transparent traceability along our supply chains and meeting the environmental and social standards.

In addition, we take a proactive approach to identify, manage and remove hazardous substances in all our products and processes to ensure safe use, ahead of legislation, future-proofing our products against changes in regulations.

We substantiate our research and efforts into alternative feedstocks and circularity of our products or packaging by continually updating our product Life Cycle Analyses.

We further increase the existing activities aimed at preventing littering, including educational projects for our customers and local communities in the countries in which we operate.

Key levers to responsible consumption and production

-

Re-gauging materials to minimise end user waste

-

Designing devices with longer service life

-

Introducing post-consumer recycled and renewable raw material, certified by ISCC or FSC

Water: promoting best practices

El agua juega un papel crucial en varias actividades de Mölnlycke, incluida la producción de materias primas, la fabricación de productos (como la producción de espuma), la limpieza, la refrigeración y el saneamiento. En particular, la producción de guantes es un proceso que requiere mucha agua. Nuestra planta de fabricación de guantes Kulim Hi-Tech Park en Malasia cuenta con la certificación LEED y recibió la puntuación más alta posible en la categoría de eficiencia del agua.

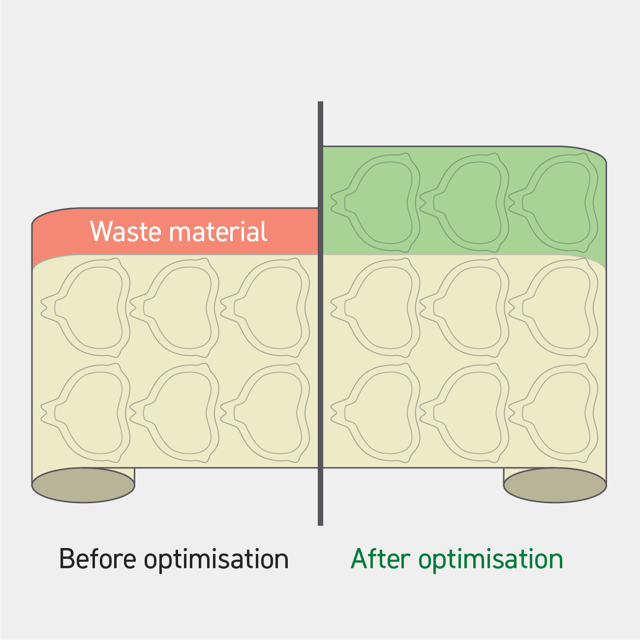

Waste reduction through manufacturing innovation

Con el proceso mejorado de corte ancho, la fábrica de Maine redujo la cantidad de desechos enviados al vertedero en 30 toneladas por mes. La optimización también aumentó el número de apósitos producidos a partir de un rollo en un 50%.

Helping customers reduce waste

Studies show that switching from single-packed medical supplies to our customisable Mölnlycke® ProcedurePak trays can reduce packing waste with up to 90 %, while saving valuable time in preparation.